CTE = 2 x 10-6 °F

900°F Service Temp

Durable & resilient to

damage for long-life use

80% lighter than Invar

75% lighter than steel

50% lighter than aluminum

Does not corrode, rust,

or oxidize. No shelf life.

Short heat up & cool down

Stocking Program Available

Tool Fabrication Steps

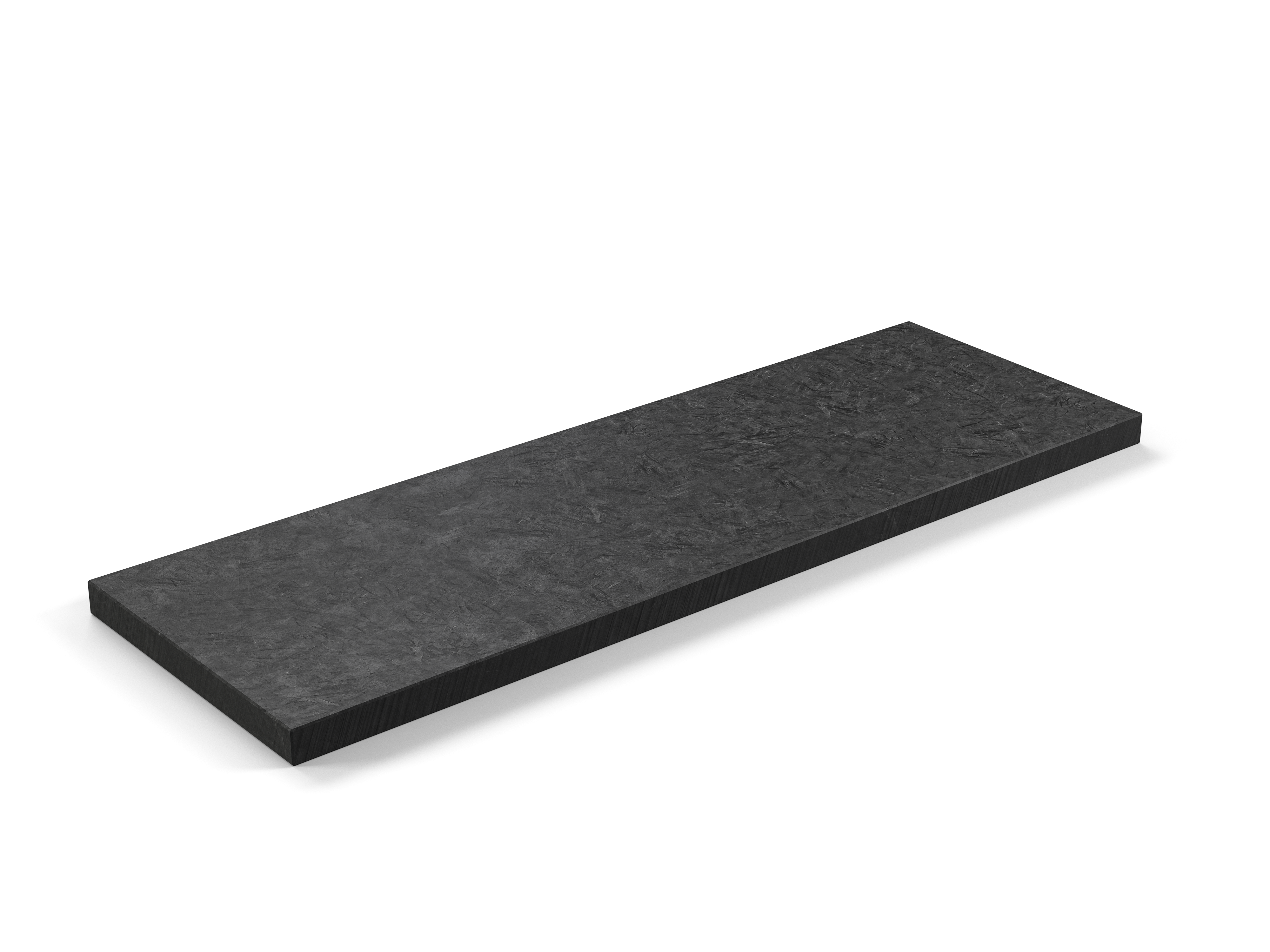

Unique Billet

Purchase BlackBoard billet. Since the material has no shelf life and does not deteriorate it can be kept on-hand for immediate use.

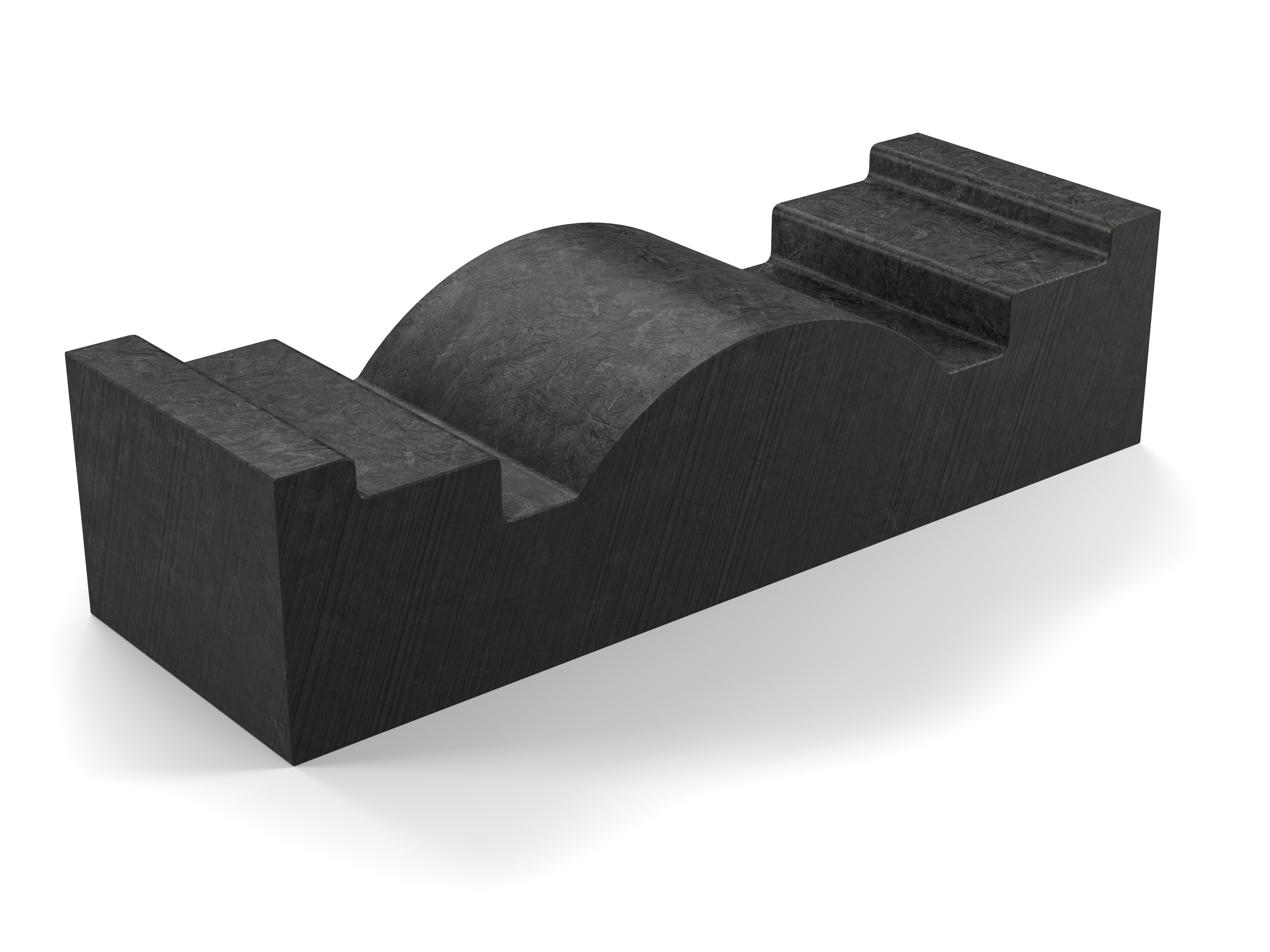

Machine & Surface Coat

Machine tool surface, sand for smooth surface, and apply glossy finish coat for high quality tooling surface.

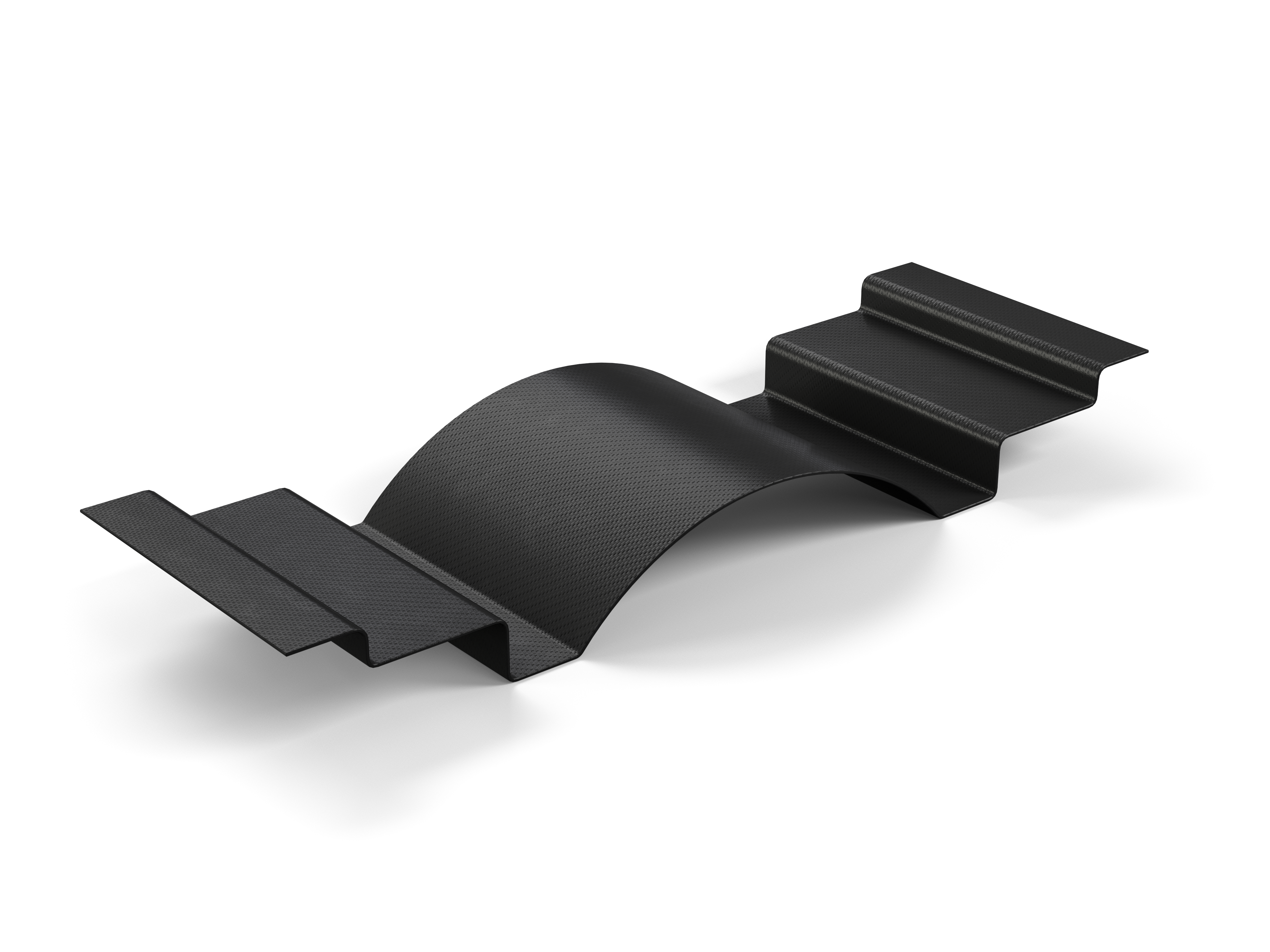

Mold

Apply standard release agent and mold component!

Want to Learn More?

To request the Harcourt TDS document with more information on Blackboard™, enter your information below and our team will be in touch with you shortly! Don’t forget to check your spam folder.

"*" indicates required fields